Fineblanking

Fineblanking at Jagemann™ Stamping is time efficiency at its best: Jagemann™’s fineblanking is capable of condensing several steps of typical traditional stamping. In a single step, Jagemann™’s fineblanking technique can produce a part that would otherwise take hours of manual labor, parts, and operation. Jagemann™’s fineblanking eliminates high labor metrics and related costs.

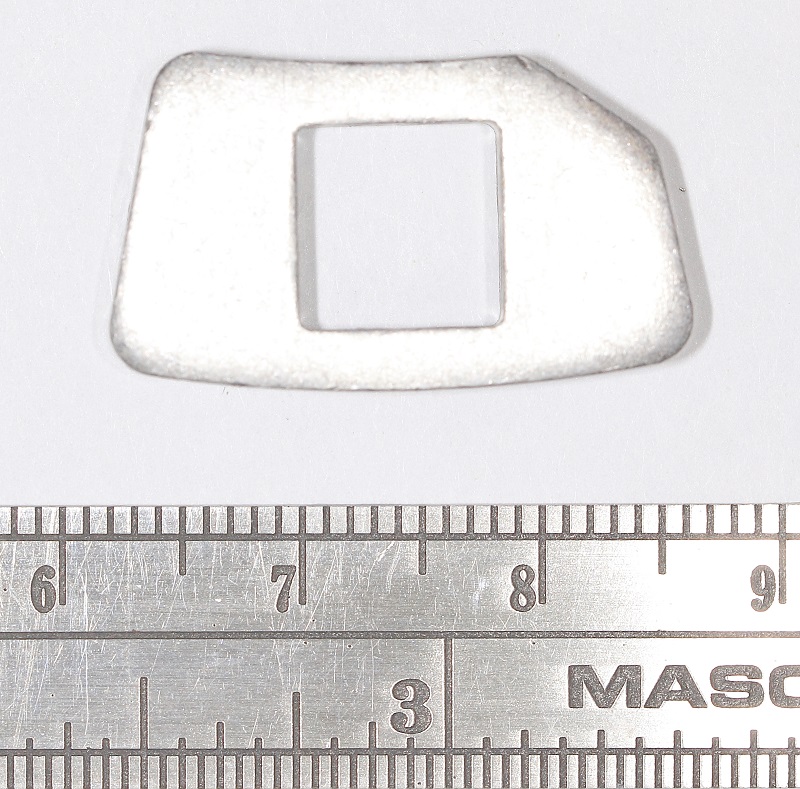

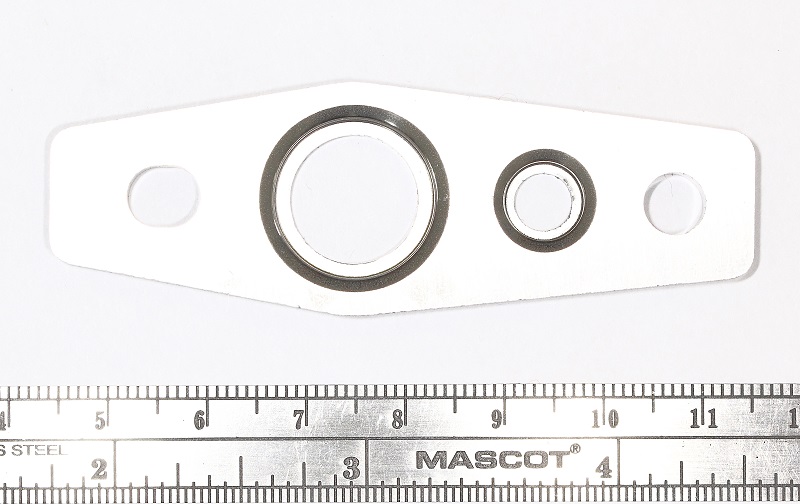

Jagemann™’s fineblanking process has been recognized for its versatility and efficiency by the home hardware, medical, and automotive industries. If you’re looking for fully-sheared, crisp edges and the ability to hold close tolerance, true position, and profile, fineblanking at Jagemann™ is here to help. With over forty years of experience in fineblank engineering, Jagemann™’s mission is to deliver only the best to our customers through faster, smarter, and cost-effective solutions.

Tooling is designed in house by Jagemann™ skilled engineers, and once a tool is created, Jagemann™ Stamping maintains it for its life – saving more costs for you the customer.

Heat-treating and surface treatments are all included in the process, meaning Jagemann™ fineblanking customers are not troubled with additional services or suppliers. If you have a stamping project in mind, Jagemann™’s integrated approach will work for you.

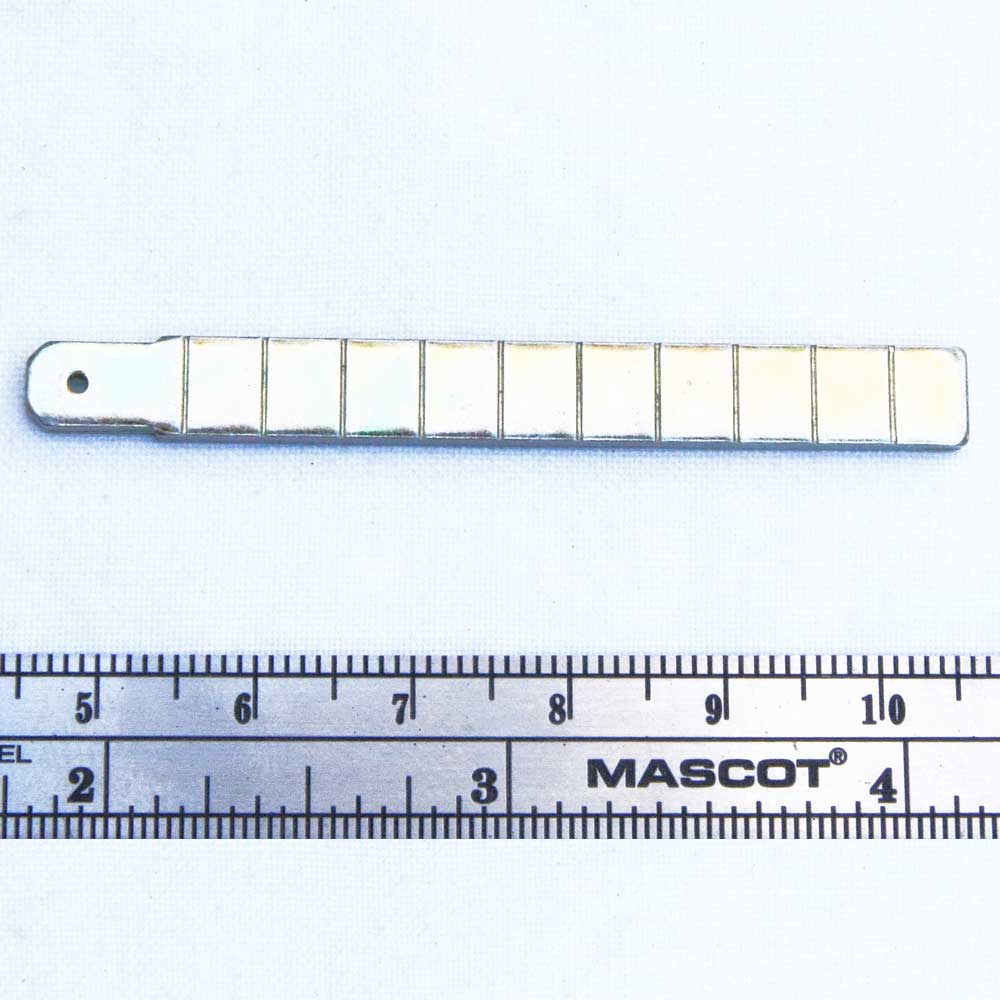

Fineblanking at Jagemann™ avoids the deformation or bulging that occurs when a punch makes contact with the sheet. Jagemann™ ensures the manufactured product has full contact with the surface on the edge of the part. This creates the critical flatness a gear’s tooth, for example, will need to be fully engaged with the gear in order to connect all through the circumference of the part. During the cutting process, Jagemann™ uses three high-pressure pads for its fineblanking special press that keep the metal flat, avoiding deforming during the punch’s entry.

Jagemann™ is a full service stamping company that couples the latest technology with the best people in our state of the art manufacturing facility. Jagemann™ is constantly exceeding our client’s expectations for what Fineblanking can be. Using raw materials, Jagemann™ utilizes stainless steel, aluminum, cold rolled steel, high carbon steel, nickel, brass, galvannealed steel, copper, and HSLA (high-strength low-alloy) steel. Jagemann™ takes every material into consideration so you don’t have to. With each project our clients come to us with, Jagemann™ makes sure that we are using the best materials out there to ensure the perfect end product.

Raw Materials: Stainless Steel (304, 305, 316, 430 & 434), Aluminum (3003, 5052, 6061), Cold Rolled Steel (1008, 1010), High Carbon Steel (1035, 1074), Nickel and Pre-plated Steel, Galvannealed Steel, Brass (80-20, 80-15, 70-30), Copper, HSLA.

Raw Material Thickness: 0.040″ to 0.375″

Tooling is designed in house by our skilled engineers, and once a tool is created, Jagemann™ Stamping maintains it for its life, which translates to cost-savings for the customer.

Additionally, heat-treating and surface treatments are all included in the process, meaning our customers are not troubled with additional services or suppliers.

If you have a stamping project in mind, our integrated approach will work for you.