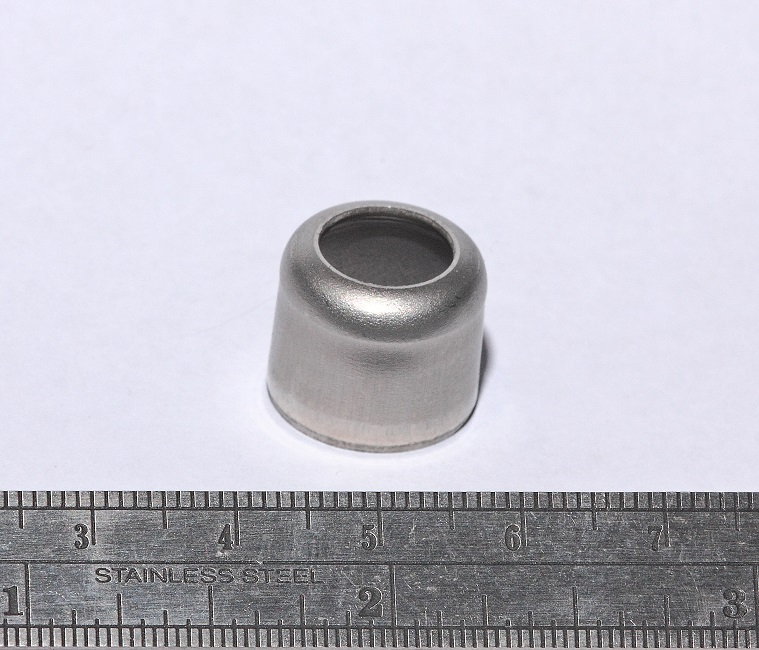

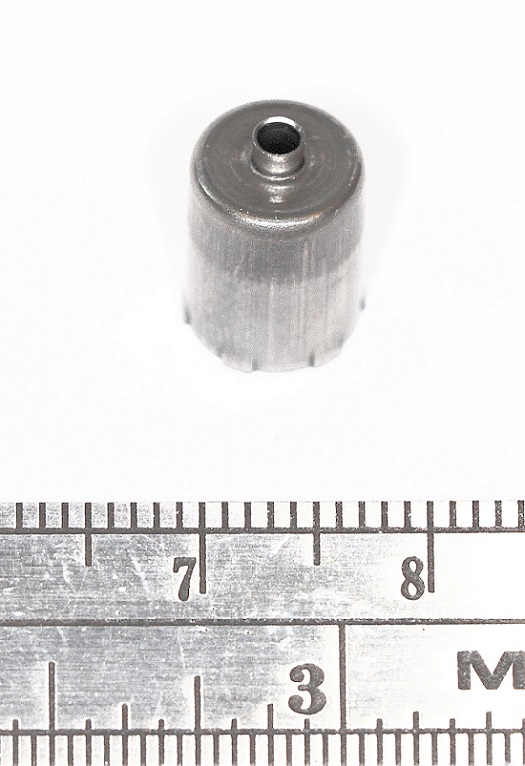

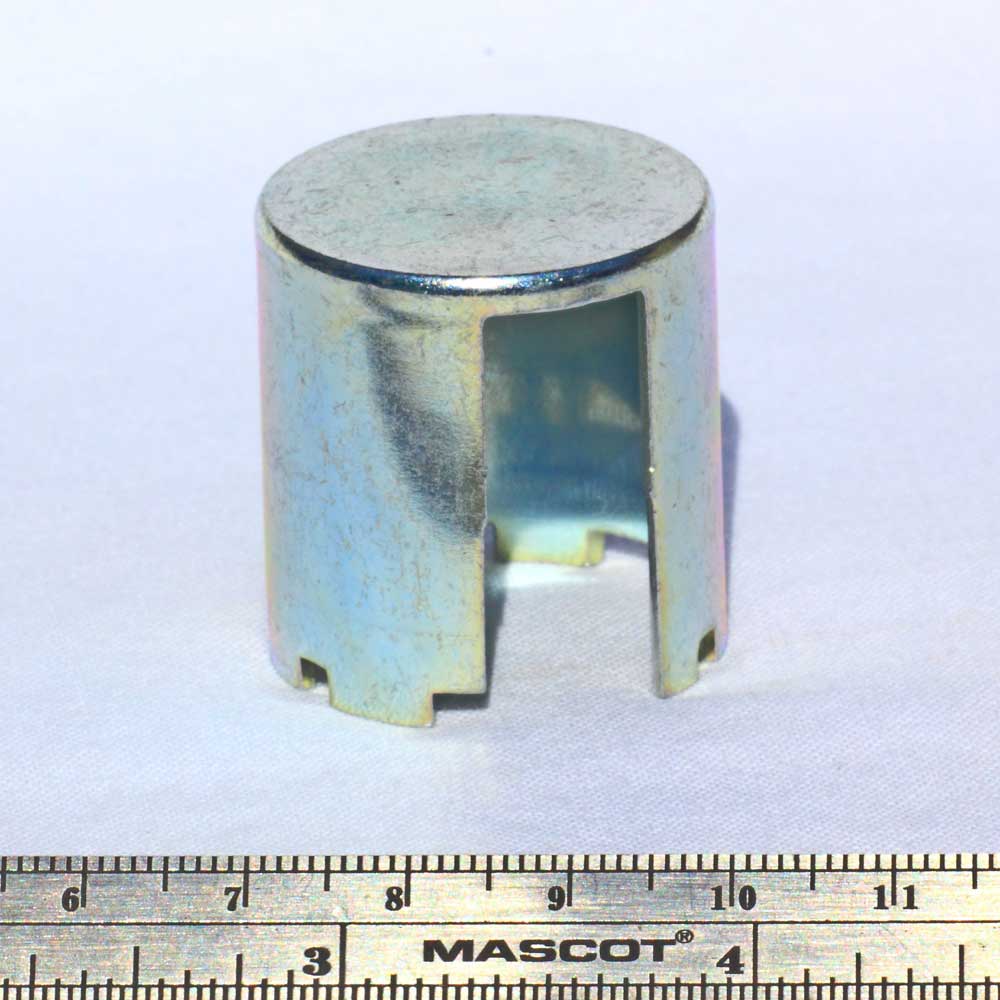

Deep Draw

Deep drawing refers to the metal forming process in which a small disc of metal, or cup, is drawn into a forming die by the action of a mechanical punch. The process is considered deep-drawing because of the increase of the cup’s depth in relation to its diameter through the start of the process to the finish.

We have over 100 years of engineering experience within our deep draw capabilities, primarily serving the automotive and industrial markets.

Presses ranging from 15 to 330 tons.

Raw Materials: Stainless Steel (304, 305, 316, 430 & 434), Aluminum (3003, 5052, 6061), Cold Rolled Steel (1008, 1010), High Carbon Steel (1035), Nickel and Pre-plated Steel, Galvannealed Steel, Brass (80-20, 80-15, 70-30), Copper, HSLA.

Raw Material Thickness: 0.008″ to 0.15″ / 0.2032mm – 3.81mm

Tooling is designed in house by our skilled engineers, and once a tool is created, Jagemann™ Stamping maintains it for its life, which translates to cost-savings for the customer.

Additionally, heat-treating and surface treatments are all included in the process, meaning our customers are not troubled with additional services or suppliers.

If you have a stamping project in mind, we’ll show you how our integrated approach will work for you.